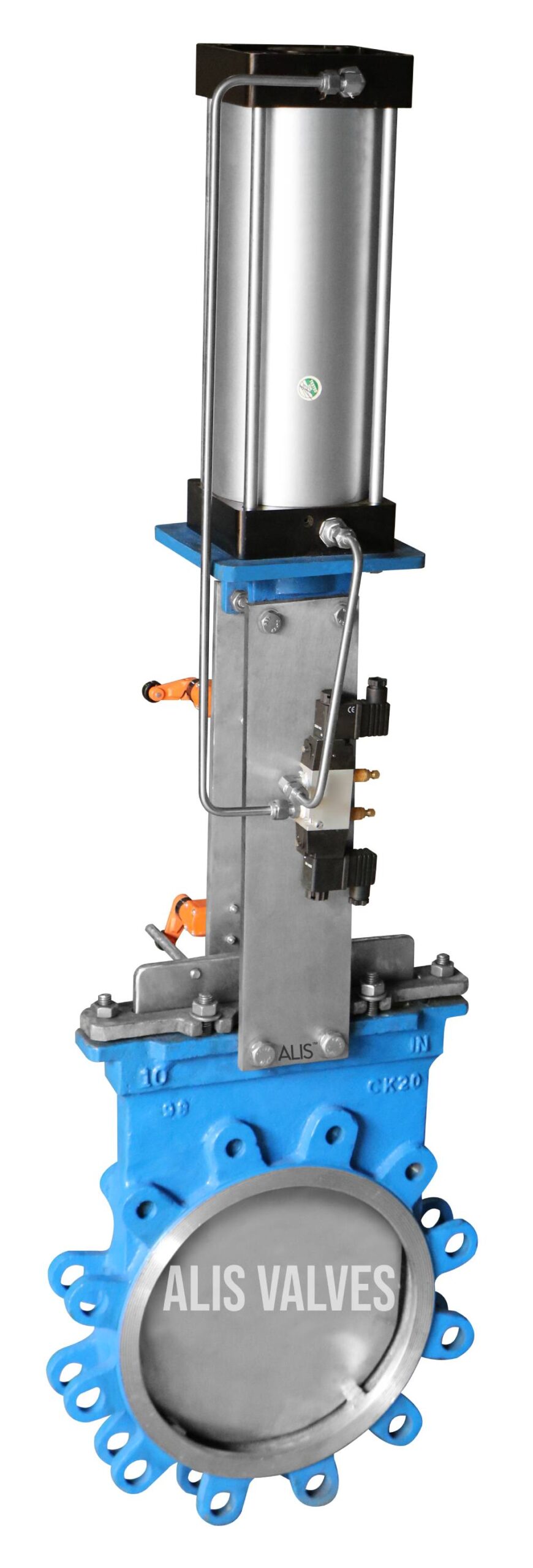

Pneumatic knife edge gate valves have become an integral part of modern industrial systems, offering unmatched precision, reliability, and efficiency. These advanced valves are specifically engineered to handle challenging applications involving slurry, powders, semi-solid materials, and viscous fluids. Industries such as mining, wastewater treatment, cement, chemical processing, and food processing rely heavily on these valve systems to ensure seamless operations and minimal downtime.

What are Pneumatic Knife Edge Gate Valve Systems?

Pneumatic knife edge gate valves are operated using a pneumatic actuator, which provides automated control over the valve’s operation. The knife-edge design ensures clean and precise cutting through dense or viscous media, preventing blockages and ensuring uninterrupted flow. These valves are particularly effective in on/off applications and where isolation of media is crucial.

The integration of innovative technologies and modern engineering designs has elevated the efficiency and performance of pneumatic knife edge gate valves, making them indispensable for industries requiring precision control.

Key Features of Innovative Pneumatic Knife Edge Gate Valves

- Precision Control: Accurate flow regulation and tight shutoff for minimal leakage.

- High Durability: Built with robust materials to withstand abrasive and corrosive media.

- Automated Operation: Pneumatic actuators enable hands-free, remote control.

- Compact Design: Space-efficient structure without compromising efficiency.

- Energy Efficiency: Optimized air consumption reduces energy costs.

- Zero Leakage: Advanced sealing technologies ensure leak-proof performance.

- Low Maintenance: Minimal wear and tear, reducing downtime and maintenance costs.

- Customizable Solutions: Tailored designs to meet unique operational requirements.

Applications of Pneumatic Knife Edge Gate Valves

These innovative valves are widely used across a range of industries:

- Mining and Minerals: Efficient handling of abrasive slurries and mineral concentrates.

- Wastewater Treatment Plants: Managing thick sludge and preventing clogging.

- Power Generation: Controlling ash and other byproducts efficiently.

- Chemical Processing: Handling corrosive and viscous fluids safely.

- Cement Industry: Regulating the flow of powdered cement and additives.

- Food and Beverage Industry: Ensuring hygienic control of fluids and semi-solids.

Advantages of Innovative Pneumatic Knife Edge Gate Valves

- Enhanced Productivity: Faster response times improve overall efficiency.

- Reduced Downtime: Reliable performance minimizes operational delays.

- Improved Safety: Leak-proof designs prevent hazardous leaks.

- Cost-Effective: Long operational life reduces replacement frequency.

- Scalable Solutions: Suitable for both small and large-scale operations.

- Smart Integration: Compatibility with automation and control systems.

Technological Innovations in Pneumatic Knife Edge Gate Valves

Innovation has played a significant role in improving the performance and reliability of pneumatic knife edge gate valves. Some key advancements include:

- Smart Sensors: Real-time monitoring for early detection of faults.

- IoT Integration: Remote valve operation and predictive maintenance capabilities.

- Improved Sealing Technology: Advanced sealing materials for zero-leak performance.

- Energy-Efficient Actuators: Optimized pneumatic actuators for reduced energy consumption.

- Corrosion-Resistant Materials: Enhanced durability in harsh environments.

How to Choose the Right Pneumatic Knife Edge Gate Valve

When selecting an innovative pneumatic knife edge gate valve, consider the following factors:

- Material Selection: Ensure compatibility with the media being handled.

- Pressure and Temperature Ratings: Match operational requirements.

- Actuator Type: Choose actuators designed for your application.

- Sealing Mechanism: Verify zero-leakage capabilities.

- Manufacturer Reputation: Opt for trusted and certified suppliers.

- Customization Options: Look for tailored valve designs.

Leading Manufacturers of Innovative Pneumatic Knife Edge Gate Valves in India

India is home to some of the most trusted manufacturers of innovative pneumatic knife edge gate valves, including:

- Aira Euro Automation: Known for precision-engineered industrial valves.

- Forbes Marshall: Renowned for durable and reliable solutions.

- Advance Valves: Experts in customized valve designs.

- Bangalore Industrial Valves: Pioneers in cutting-edge valve technologies.

- Kirloskar Valves: Trusted across industries for quality and performance.

These manufacturers prioritize innovation, quality control, and customer satisfaction, delivering products that meet global standards.

Maintenance Best Practices for Pneumatic Knife Edge Gate Valves

- Regular Inspections: Periodic checks to identify signs of wear.

- Proper Lubrication: Ensure smooth actuator performance.

- Sealing Integrity: Replace damaged seals promptly.

- Clean Valve Components: Prevent debris and build-up.

- Monitor Actuator Performance: Ensure optimal pneumatic operation.

The Future of Pneumatic Knife Edge Gate Valve Systems

The future of pneumatic knife edge gate valves lies in smarter, more efficient designs powered by IoT, AI, and automation technologies. Key trends include:

- Smart Valve Systems: Integration with cloud-based monitoring systems.

- Energy-Efficient Designs: Actuators with optimized air consumption.

- Enhanced Safety Mechanisms: Improved sealing and fail-safe designs.

- Sustainability: Use of environmentally friendly materials and processes.

Conclusion

Innovative pneumatic knife edge gate valve systems are revolutionizing industrial operations by offering precision, durability, and automated efficiency. As industries continue to demand smarter and more reliable solutions, these valves will remain a cornerstone in managing complex flow control requirements.

Whether you’re dealing with slurry, viscous fluids, or powdered materials, investing in high-quality pneumatic knife edge gate valves ensures seamless operations and long-term cost savings. Choose a trusted manufacturer to experience the true potential of these advanced valve systems.

Also Read

- ► Versatile Deli Paper: Perfect for Food Wrapping and Presentation

- ► How the SEO Company in Leeds Can Help Generate More Revenue

- ► The Benefits of Using Custom Kraft Paper for Your Business

- ► Best Finance Assignment Writer for Quick Solutions

- ► Dollar to PKR Exchange Rate: A Comprehensive Guide to Understanding Currency Conversion

- ► Custom Food Paper: Redefining Food Packaging and Branding

- ► Pressure Washing

- ► Milano Group: Redefining Fashion with GTR Hoodies and Custom T-Shirts

- ► Shuttle Service

- ► Roombae: Where Living Together Becomes Effortless

- ► Business Analyst Career Path for 2025

- ► Halim Seed: The Nutrient-Packed Superfood

- ► The Role of Lumber Takeoff Services in Accurate Project Estimations

- ► Silk Screen Printing on Shirts: Process and Benefits

- ► Affordable and Reliable: Finding the Best Taxi Service in London