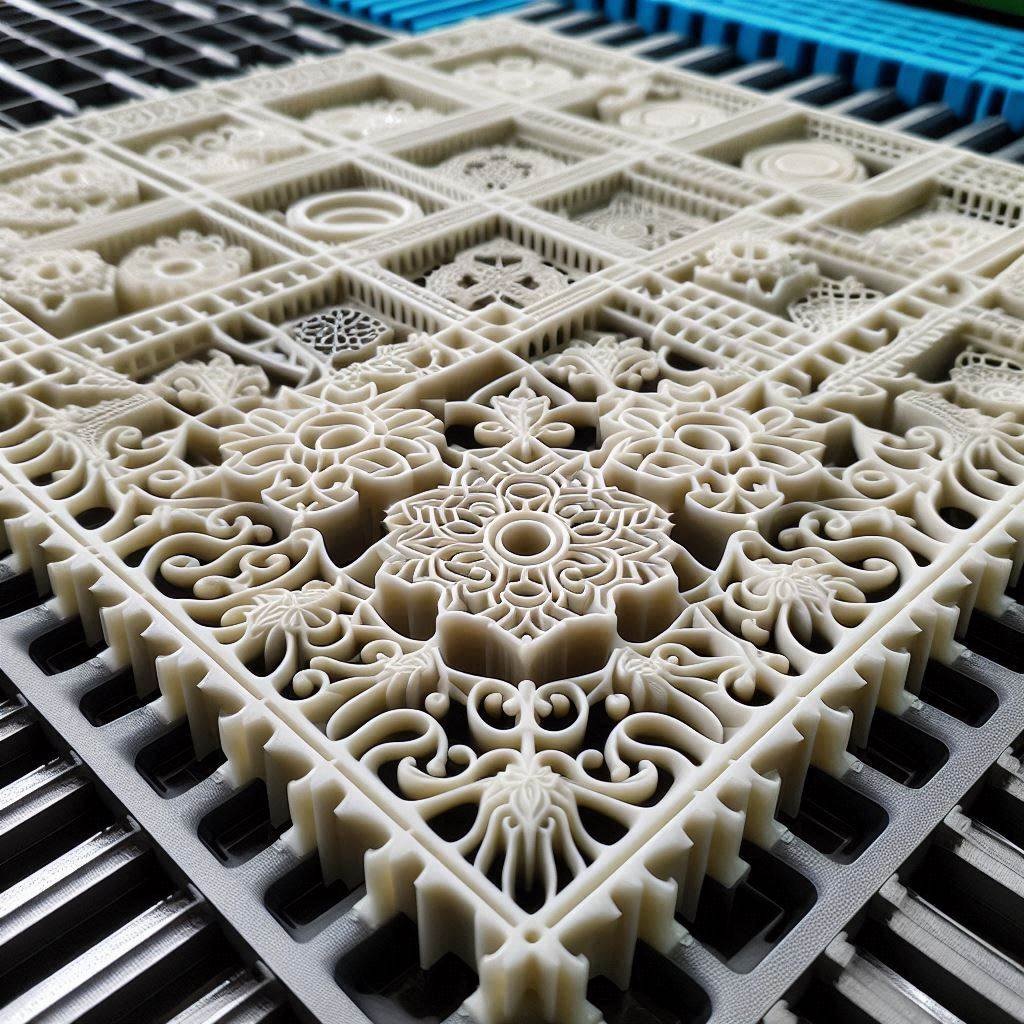

The environment that heavy machinery and chemicals along with exposure to stringent climatic factors expose industrial surroundings makes choosing the appropriate materials the right criteria to achieve security, longevity, and low expense. FRP moulded gratings is among those material solutions in India gaining prominence as well in its advantage to the Indian industries. These gratings consist of resin filled with glass fibres, which make them carry extensive strength and are light, corrosion-resistant as well. With such characteristics, they are great for a large number of applications in the industry. Here’s a closer look at the primary advantages of FRP moulded gratings used in India, for industrial application.

1. Excellent Corrosion Resistance

Fibre reinforced pultrusion moulded grating are made up of materials that are fire resistant, have high tensile strength and load capacity. That is why they are used in several industries, manufacturing units, chemical factories etc. FRP gratings can easily survive such conditions by resisting corrosive chemical environments for long periods. Traditional materials such as steel rust and corrode easily, resulting in loss of long-term service life and increasing costly repair and replacement requirements. This makes FRP gratings a reliable choice for corrosive environments commonly found in Indian industries.

2. Lightweight and Easy to Install

The FRP moulded gratings are much lighter than the metal or concrete alternatives, hence easier to handle, transport, and install in the field. Reduced weight means lower labour cost and less time for installation in India, as well as lower structural load due to light material, which can be useful if load-bearing capacity is limited or buildings are lightly constructed.

3. Non-Slip Surface for Greater Safety

Safety is always a priority in any industrial setting. FRP gratings are manufactured with a non-slip surface so that the grip and traction of the workers even on wet surfaces as well as against oils and chemicals are much enhanced. It’s especially applicable for pharmaceutical, food processing, and marine industries. The textured surface of FRP gratings avoids slips, falls, and work injuries and keeps the working area safe for everyone.

4. Durability and Longevity

FRP moulded gratings are very resistant and can sustain adverse environmental conditions like extreme temperatures, UV exposure, and heavy traffic. In India, where the temperatures shoot up, and the materials are exposed to the sun and break down with time, the FRP’s UV resistance is something that would serve it as a long-lasting material for industrial use. Be it an open system exposed to light or subwater, FRPs perform the same and last similarly long.

5. Low Maintenance Required

One great advantage of the FRP is that the grate requires very minor maintenance. These are not needed much for frequent cleansing, painting again, and especially replacement for a reason such as rusting due to friction from wear and tear. Their structural integrity and appearance are ensured for a long time; they don’t have to undergo constant maintenance, which saves the long-term cost associated with maintenance and increases operational efficiency. The low maintenance nature of FRP gratings is particularly beneficial in industries that operate in remote or hard-to-reach locations in India, where regular maintenance could be costly and time-consuming.

6. Customizable Design

These have a high range of versatility such that they could be designed into any industrial usage. Whether its size, or load-bearing strength, or whether it is their colour, manufactures can design to an FRP to suit the industry’s needs at will. In industrial sectors in India, this assures that FRP gratings find appropriate use in each of the country’s diverse fields, from those of factories, chemical plants and water treatment installations to marine facilities and environments.

7. Eco-Friendly and Sustainable practices in FRP grating manufacturing units

Manufacturers must adhere to good manufacturing practices and ecofriendly materials that can be reused without affecting our environment. Therefore, their replacement takes place less often. Also, the material is light in weight but strong. Hence, there is less carbon footprint concerning the transportation and installation process.

Conclusion

FRP Moulded Gratings India offer a lot of benefits that make it an ideal choice for India’s industrial markets. They are highly corrosion-resistant, light in weight, slip-resistant surface, durable, and very low in maintenance, thereby making FRP grating appropriate to meet diversified demands of varied sectors, like chemicals and pharmaceuticals, wastewater treatment plants, and manufacturing areas. FRP moulded gratings therefore come out as an intelligent investment to enhance the efficiency of operation, safety, and long-term performance of industrial activities. Therefore, in light of this, FRP gratings can be the option for sectors to upgrade their infrastructure with reduced costs of maintenance, while safety at work is upgraded.

Also Read

- ► A Guide on Styling Women Jackets with Different Outfits

- ► Can Cisco GLC-SX-MMD Provide Your Network with Better Redundancy?

- ► Is Your Business Ready for the Cloud? Choosing the Right Cloud Computing Provider

- ► SBI Long-Term Equity Fund: Simple Way to Save Taxes

- ► What You Need to Know About Cisco GLC-SX-MMD’s Compatibility with Other Devices

- ► Where Can You Book the Best Last-Minute Flights?

- ► Get Expert Engineering Assignment Help in Melbourne

- ► Cisco GLC-TE: The Future of Data Transmission in Network Engineering

- ► Is Cisco GLC-TE the Right Choice for Your Business’s Fiber-Optic Needs?

- ► How Technology Shapes Modern School Education

- ► Heavy Rain Leads to Devastating Truck Accident

- ► Choosing the Right Boomi Integration Consulting Partner for Your Business

- ► Lordsexch: An Ultimate Online Cricket ID Provider In 2025

- ► NetSuite Integration for Subscription Businesses: Automating Billing and Revenue Recognition

- ► Everything You Need to Know About ISPL Season 2: Schedule & Live Scores